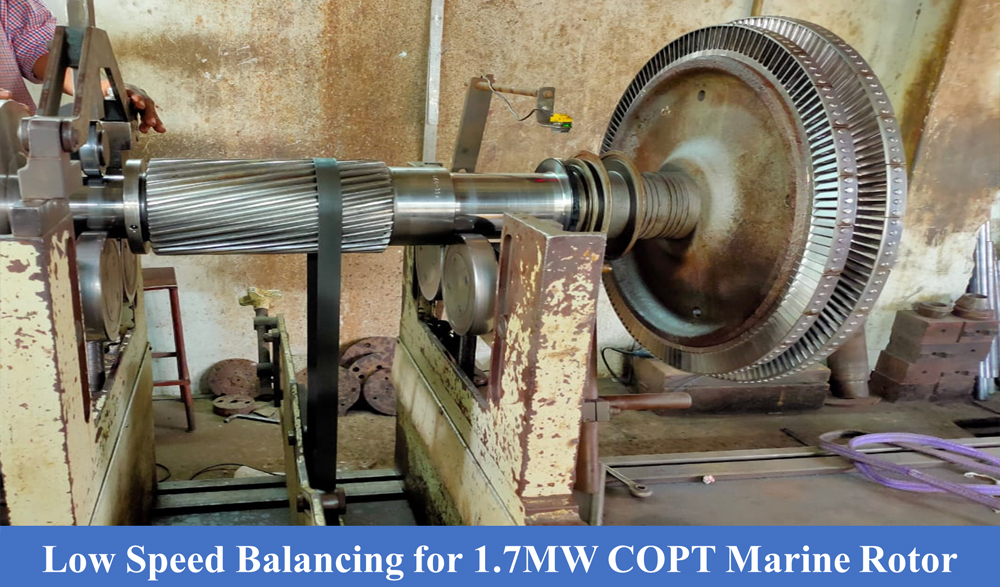

Dynamic Balancing Facilities

Unbalance in rotating components is caused by the displacement of the mass centreline from the rotor axis by an eccentricity in the distribution of the rotor mass. Balancing is the correction of this phenomenon by the removal or addition of mass to the component to compensate for centreline error. In practical terms, balancing "is the process of attempting to improve the mass distribution of a body so that it rotates in its bearings without unbalanced centrifugal forces."(ISO 1940/1 Mechanical vibration - Balance quality requirements of rigid rotors).

Requirement Of High-Speed Balancing

Rated Speed Balancing is for high-speed rotating components where standard, "low speed" balancing (less than 2000 rpm) is not sufficient. Typically, High speed balancing is required when additional vibration modes (critical speeds) or radial growth of components are encountered at operational speed.

Properly balanced rotating components minimize vibration and noise, extend the life of bearings, and help to ensure a component intended levels of safety, reliability, and performance.